Location:

HyChem industrial plant, Póvoa de Santa Iria (Portugal)

Energy Intensive Industry:

Chemicals

Involved Technologies:

CO2 capture of variable & low-concentrated flows, rich-lipids microalgae cultivation in closed PBRs, HTL to high-energy content bio-oils

Produced RECs:

Bio-oils

Key participants:

HCH, NOVIS, A4F, CIRCE

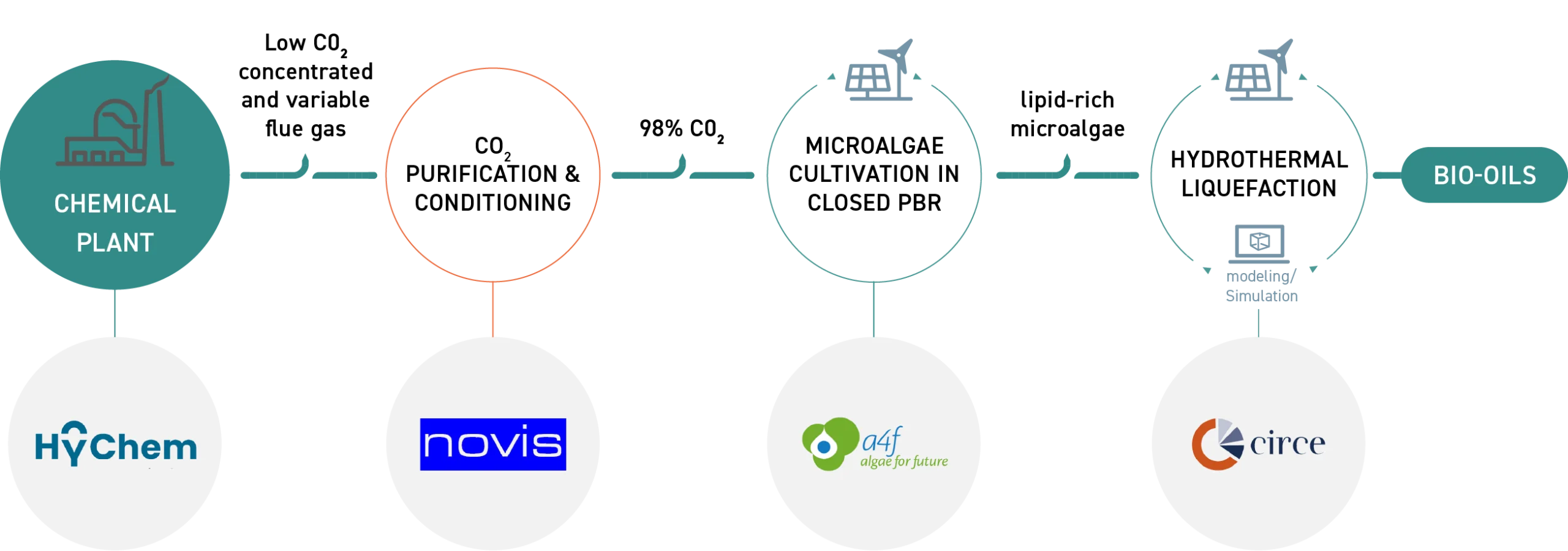

With the aim of obtaining biofuels and green chemical products from microalgae, considered as one of the key emerging feedstocks in oncoming biorefineries and which represents profitable business niches, the challenge of the CAPTUS demonstration site 2 located at HyChem’s Industrial Site in Póvoa de Santa Iria (Portugal) is the integration of the following technical solutions: CO2 capture from fluctuating gas streams, valorization of CO2 for microalgae production and its subsequent conversion to bio-oil as final renewable energy carrier. These new and recent technologies have not yet been integrated together in a single demonstrator at this scale and achieving technical and economic viability. Additionally, neither of these processes corresponds to turnkey technologies, so each of the integrated units will have to be designed for this specific project.

The demonstration site 2 will demonstrate a complete CCU process by means of an innovative technology based on (1) CO2 captured & purification, (2) a microalgae cultivation in tailored-designed photobioreactors (PBRs) and (3) hydrothermal liquefaction (HTL). The whole value chain to convert the CO2 flue gas coming from the chemical plant into high energy content bio-oils will be developed, optimized and demonstrated at HCH under real industrial conditions.

This combined carbon capture-conversion process comprises three stages:

CO2 purification and conditioning

Novis will deploy an alternative strategy which consists of removing the unwanted gases (e.g., N2 or O2), instead of adsorption concentration, using highly energy efficient technologies that have already been successfully proven in other industry sectors.

Microalgae cultivation in closed PBR

A4F will demonstrate an integrated solution for transforming the captured CO2 by its consumption in PBRs for microalgae cultivation. The whole unit, installed at HCH facilities, will be a showcase of a replicable innovative solution that combines gaseous effluents of a chemical industry with algal fuel production.

Hydrothermal liquefaction

By deploying the HTL technology, the lipid-rich microalgae obtained will be converted into a crude oil under high temperatures and high pressures, thus enabling the production of high-energy content bio-oils. CIRCE will carry out experimental designs regarding microalgae HTL suitability for biofuel production and CERTH and GF will assess bio-oil quality and upgrading routes. As a result, a circular economy approach onto CCU shall be achieved.

The renewable energy carriers (RECs) produced in this process are bio-oils, an organic mixture obtained from the HTL of the feedstock (microalgae in this case), which is subjected to high temperatures (200-350 ºC) and pressures (5-15 MPa). Substrate macromolecules such as cellulose, fatty acids and proteins are broken down into high-range hydrocarbon mixtures. After proper purification steps are applied, the recovered biocrude oil can undergo direct combustion or upgrading to yield oils with gasoline/diesel properties that can then satisfy multiple energetical needs, consolidating a complete circular economy perspective.

Production of biofuels through HTL from algae produced with CO2 captured from industrial emissions is still underexploited in Europe, for which CAPTUS is expected to boost its adoption among EII sectors as it offers new biofuel production opportunities.